Quick Price Lookup

Shop Products

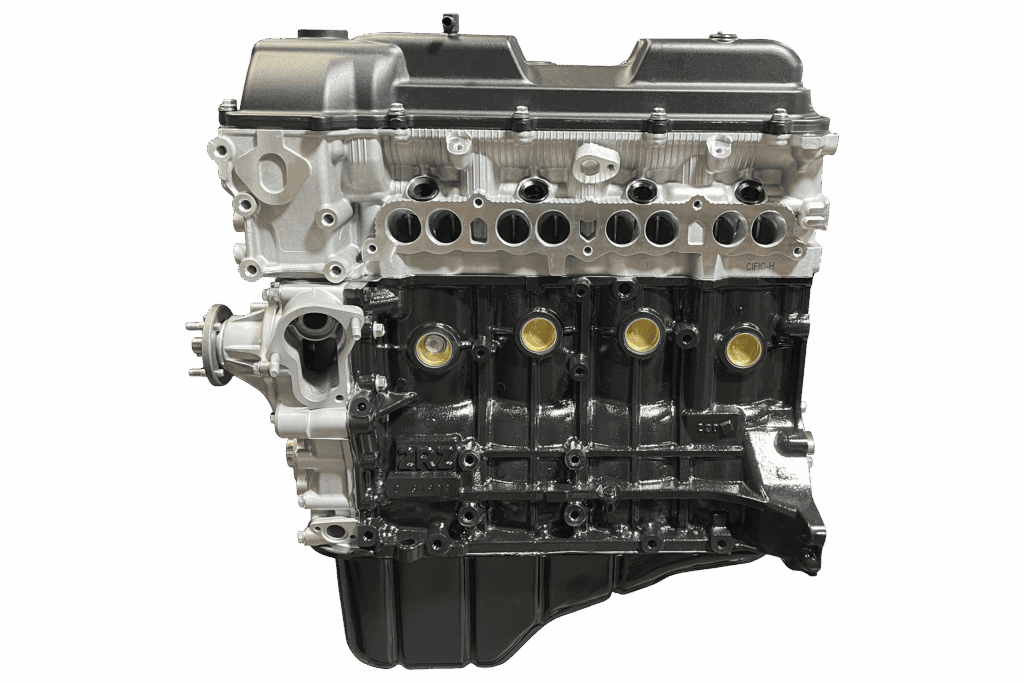

Remanufactured Gasoline Engines

Re-manufactured gasoline engines with all the updates & improvements to get you back on the road with confidence!

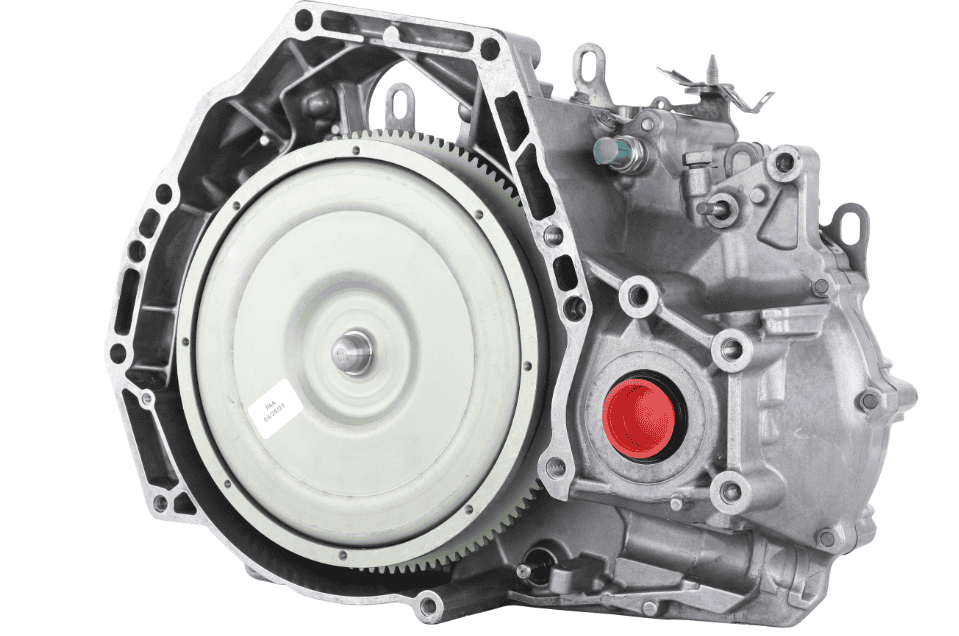

Remanufactured Transmissions

Re-manufactured transmissions with all the updates & improvements to get you back on the road with confidence!

Remanufactured Diesel Engines

Re-manufactured diesel engines with all the updates & improvements to get you back on the road with confidence!

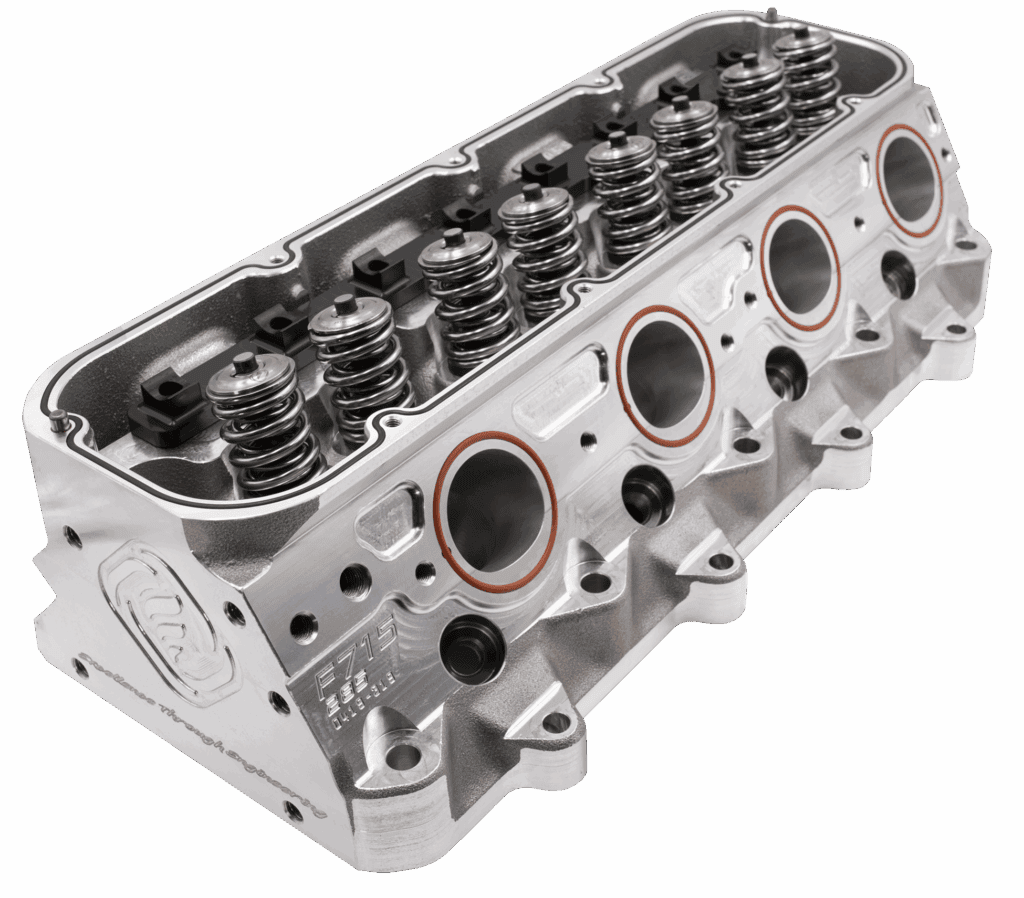

Remanufactured Cylinder Heads

Re-manufactured cylinder heads with all the updates & improvements to get you back on the road with confidence!

High Performance Engines

Fraser Engines & Transmissions is proud to offer high-performance engines for those seeking more power or restoring a classic car.

NEW Turbochargers

Fraser Engines & Transmissions is proud to now offer NEW OEM Turbochargers!

Remanufactured Transfer Cases

Fraser Engines & Transmissions is proud to now offer remanufactured transfer cases!

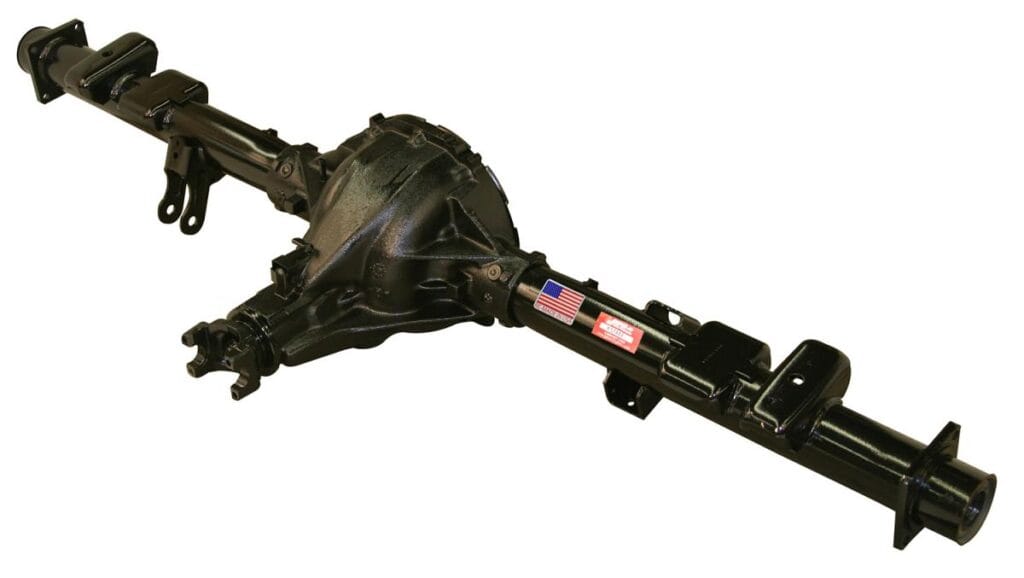

Differentials

Fraser Engines & Transmissions is proud to now offer remanufactured differentials!

Certified Used Products

Fraser Engines & Transmissions is proud to offer certified used engines & transmissions!

More Products

Fraser Engines has proudly helped tens of thousands of drivers get back on the road with reliable, high-quality engines and transmissions built to last.

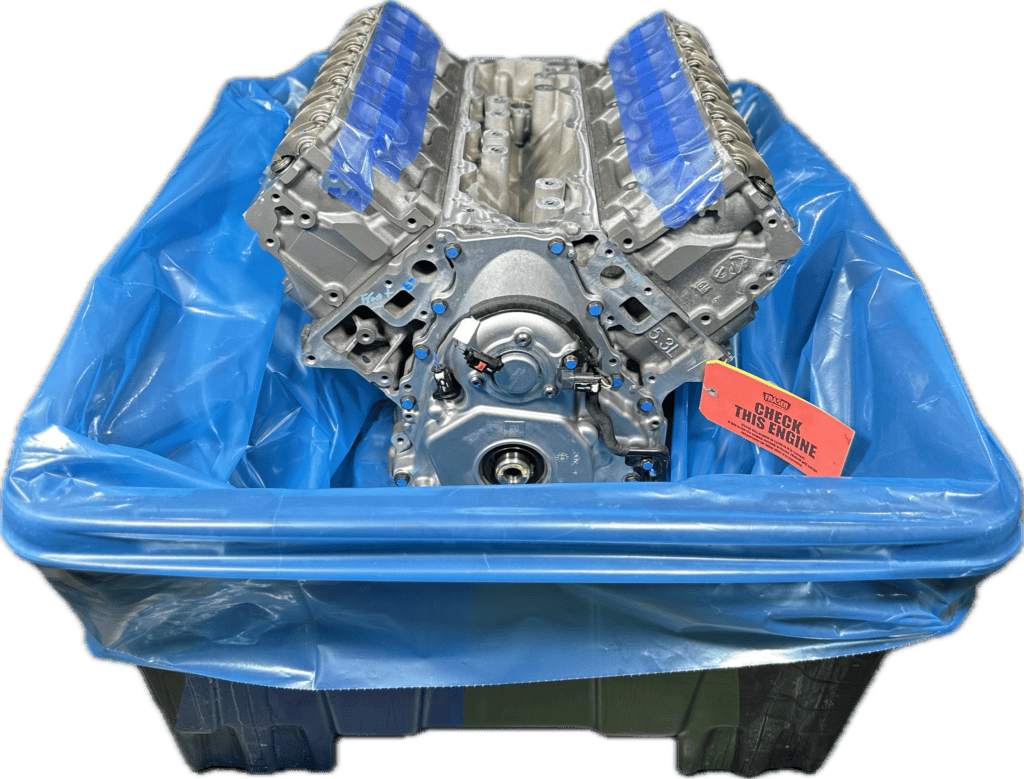

Robert White

2009 Chevy 1500 5.3L Engine

I have been a customer of Fraser Engine Company since 2019 when I purchased my 5.3L engine and I must honestly say my experience with the company has been very positive and pleasant. Customer service and communication is top notch. Always respond to my phone calls, emails, and text very quickly and if for some reason you have any issue they are quick to resolve and they stand by their warranty 100%. I will definitely look to Fraser Engine company again if I ever need an engine or transmission. “Thanks Fraser for getting my truck back on the road again”. Shipping was very quick. Engine actually runs better and seems stronger than the original. Very happy customer.

Brian Preisinger

2002 Dodge Dakota 4.7L Engine

just installed my 2nd motor from Fraser, first one was in my 2002 dodge dakota Oct 2022 and now im doing my 2001 dodge dakota Aug 2023! great people to deal with on the phone easy shipping and core return was awesome with there crate design!!

Samuel Craven

2007 Ford F-150 5.4L Engine

Great and helpful

Patrick Scallt

2005 Ford F-150 5.4L Engine

Talked to John in sales originally. I thought he said engine would ship in 7 to 10 days but it didn't. Laurie Fraser called me later and apologized. I think I got it maybe three weeks later not sure. Looked nice but no one at the office told me I needed to buy a turbo separately. Engine had a red tag on it explaining that. Someone from the office should have told me that right away but didn't.. Glad to have it installed now. Have changed the oil in it twice already. Mechanic said oil looked clean

Josh Fuqua

2013 Jeep Grand Cherokee 3.6L Engine

Excellent experience from the beginning to the end. The salesperson was knowledgeable and gave me the info I needed in order to make the best decision. The delivery was on time (actually 3 days earlier than I was told by the salesperson), and I was able to track the delivery so that we were ready. The engine is already in and halfway broken in, and with as little pedal as I am giving it, the torque difference from the exact same motor is noticeably better.

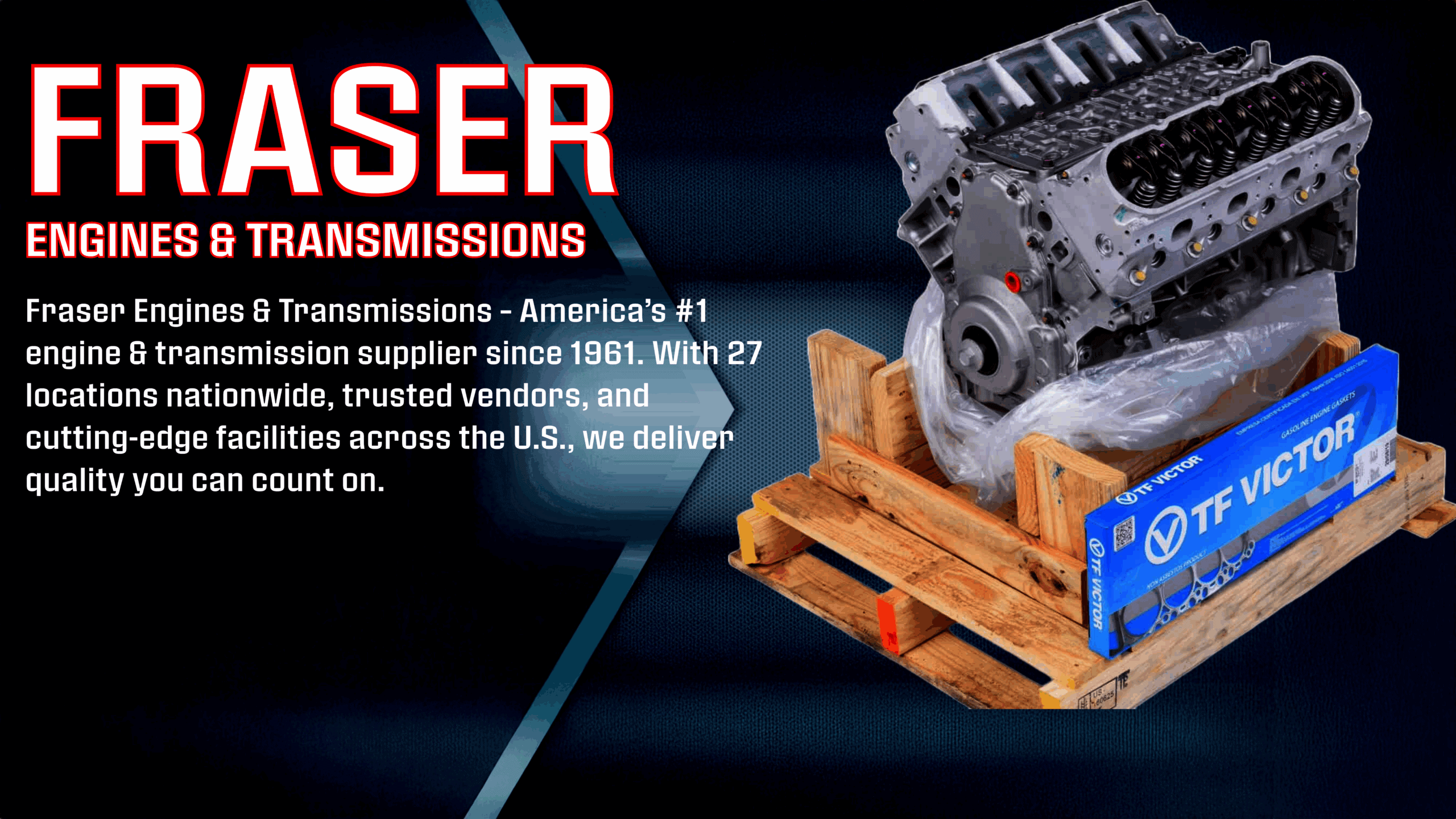

THE FRASER DIFFERENCE

At Fraser Engines, we streamline the engine buying process to ensure it’s as seamless as possible. Why go through online engine brokers when you can buy directly from the manufacturer? With thousands of engines and transmissions in stock across multiple distribution centers, we are equipped to get your vehicle running and back on the road quicker than anyone else.

With over six decades of expertise in the remanufactured engine and transmission industry, Fraser Engines is the authority in delivering high-quality, reliable solutions. This isn’t just our business; it’s our specialty, and we excel at it more than anyone else in the field.

Our commitment to excellence is evident in our customer feedback: with over 9,000 Google reviews and an impressive 4.8-star rating, our customers’ satisfaction speaks volumes. We’re not just claiming to be the best; our customers confirm it.

Browse Our Extensive Inventory Today

Explore our selection and let Fraser Engines help get you where you need to be. Experience the Fraser difference – quality, speed, and reliability that you can trust.

MULTIPLE NATIONAL DISTRIBUTION CENTERS

At Fraser Engines, we streamline the engine buying process to ensure it’s as seamless as possible. Why go through online engine brokers when you can buy directly from the manufacturer? With thousands of engines and transmissions in stock across multiple distribution centers, we are equipped to get your vehicle running and back on the road quicker than anyone else.

With over six decades of expertise in the remanufactured engine and transmission industry, Fraser Engines is the authority in delivering high-quality, reliable solutions. This isn’t just our business; it’s our specialty, and we excel at it more than anyone else in the field.

Our commitment to excellence is evident in our customer feedback: with over 9,000 Google reviews and an impressive 4.8-star rating, our customers’ satisfaction speaks volumes. We’re not just claiming to be the best; our customers confirm it.

Browse Our Extensive Inventory Today

Explore our selection and let Fraser Engines help get you where you need to be. Experience the Fraser difference – quality, speed, and reliability that you can trust.

LEADING THE WAY

Fraser Engines & Transmissions is proud to lead the industry in innovation, quality, and customer satisfaction. As a nationwide leader in remanufactured powertrain products, we set the standard with our advanced engineering, cutting-edge remanufacturing processes, and one of the most comprehensive warranties in the business. Our commitment to excellence ensures every engine and transmission we deliver meets or exceeds OEM specifications—offering better-than-new reliability and performance. Whether you’re a DIY enthusiast, repair facility, or dealership, Fraser is the name trusted coast to coast. When it comes to getting you back on the road—Fraser is truly leading the way.

CHECK US OUT ON YOUTUBE

Who Makes the Best Remanufactured Engines? The Answer is Clear: Fraser Engines

When it comes to remanufactured engines, Fraser Engines stands above the competition. Our precision-built crate engines are engineered to deliver unmatched performance, durability, and reliability, making us the #1 choice for replacement engines. Here’s why Fraser Engines dominates the industry and why you should choose us for your next remanufactured powertrain solution.

Unrivaled Craftsmanship & Expert Engineering

At Fraser Engines, remanufacturing engines isn’t just a process—it’s an art. Our ASE-certified technicians and master machinists bring decades of industry expertise to every build, ensuring each remanufactured engine meets or exceeds OEM specifications. Our commitment to quality craftsmanship means that every crate engine we produce is built with precision and attention to detail, delivering the power and longevity you need for your vehicle.

✅ Built by skilled technicians with decades of hands-on experience

✅ Remanufactured to exacting OEM standards for superior performance

✅ Premium-grade components used in every rebuild

Cutting-Edge Remanufacturing Technology

Fraser Engines leverages the latest advancements in engine remanufacturing technology to deliver high-performance replacement engines that outperform the competition. Our facility is equipped with:

🔧 Computer-aided design (CAD) technology for precise blueprinting

🔧 State-of-the-art CNC machining to ensure flawless accuracy

🔧 Industry-leading dyno testing to guarantee optimal horsepower and torque

By integrating advanced remanufacturing techniques, we ensure that each rebuilt engine meets the highest standards of performance and reliability.

Industry-Leading Technical Service Bulletin (TSB) Updates

Unlike many remanufactured engine suppliers, Fraser Engines goes the extra mile by incorporating all major OEM Technical Service Bulletin (TSB) updates into our remanufactured crate engines. This ensures:

✔ Factory-identified issues are addressed before the engine leaves our facility

✔ Upgraded components and improved designs for enhanced longevity

✔ Superior reliability compared to standard rebuilt engines

Our commitment to continuous improvement means you’re getting a remanufactured engine that includes the latest engineering enhancements for peak performance.

Stringent Quality Control & Performance Testing

At Fraser Engines, quality assurance is at the core of our remanufacturing process. Every remanufactured engine undergoes a multi-point inspection and is tested under real-world conditions to guarantee:

✔ Zero-defect engines with unmatched reliability

✔ Comprehensive oil pressure, compression, and leak-down testing

✔ Premium engine components for long-term durability

Our strict quality control measures ensure that every remanufactured engine meets our exacting standards before leaving our facility.

Best-In-Class Warranty Coverage

Fraser Engines stands behind the quality of our remanufactured crate engines with industry-leading warranty options, including:

🔒 Up to 5-Year / Unlimited-Mile Extended Warranties

🔒 Comprehensive coverage on parts and labor

🔒 Hassle-free claims process for peace of mind

No other remanufactured engine provider offers the same level of confidence and protection as Fraser Engines.

A Legacy of Excellence Since 1961

For over 60 years, Fraser Engines has been the trusted name in remanufactured engines. Our commitment to quality, innovation, and customer satisfaction has solidified our reputation as the #1 engine remanufacturer in the industry.

🏆 Back-to-back industry awards for leading sales in powertrain products

🏆 Thousands of satisfied customers nationwide

🏆 A proven track record of excellence spanning decades

When you choose Fraser Engines, you’re not just buying an engine—you’re investing in a legacy of reliability, performance, and expertise.

Fraser Engines: The Best Remanufactured Engines, Built for Maximum Performance

If you’re searching for the best remanufactured engine for sale, Fraser Engines is the clear choice. Our high-performance crate engines deliver the power, longevity, and reliability you need, backed by our industry-leading warranty and expert craftsmanship.

🔹 Find the perfect engine for your vehicle today!

📞 Call us now at (800) 731-3177

📧 Email: sales@fraserengines.com

🌐 Visit us online: fraserengineco.com

Don’t settle for less—choose Fraser Engines and experience the best in remanufactured powertrain solutions! 🚗🔧🔥

OUR MAIN PRODUCTS

Expertise and Reliability: With over 60 years in the engine remanufacturing industry, our skilled technicians bring unmatched expertise to every engine we rebuild.

Wide Selection: Whether you are looking for a car, truck, or marine remanufactured engine, our extensive inventory means we have the right engine for your vehicle.

Speedy Delivery: Multiple distribution centers allow us to expedite shipping on your remanufactured engine, so you can get your vehicle back on the road faster.

Customer Satisfaction: Our commitment to quality on our remanufactured engines is backed by thousands of positive reviews, with a 4.7-star rating on Google, demonstrating our dedication to customer satisfaction.

Direct Purchase Advantage: Buying directly from us ensures you receive premium-quality remanufactured engines at competitive prices, without the intermediaries.

Explore Our Remanufactured Engines Today

Explore our website to browse our selection of top-quality remanufactured engines. Let Fraser Engines and Transmissions power your vehicle with robust and reliable engines. Contact us today to find the perfect engine solution tailored to your needs.

Top-Quality Construction: Each crate engine is meticulously assembled using brand-new components, ensuring your engine is built to last and performs at its best.

Broad Range of Options: We offer a diverse selection of crate engines for various makes and models, ensuring you find exactly what you need for any type of vehicle.

Competitive Pricing: Crate Engines direct from the manufacturer to your garage, our pricing is set to offer you the best value, making top-tier performance accessible without breaking the bank.

Expert Support: Our team of knowledgeable crate engine specialists is here to assist you every step of the way—from selection through installation.

Fast Shipping: With multiple distribution centers across the country, we guarantee quick and efficient delivery of your crate engine directly to your doorstep or your mechanic’s shop.

Elevate your vehicle’s performance with a professionally rebuilt engine from Fraser Engines and Transmissions. Our rebuilt engines are carefully reconditioned by expert technicians to meet the highest standards of quality and reliability. We understand the importance of a dependable engine, which is why each unit undergoes rigorous testing and quality control checks to ensure top performance and longevity.

Key Advantages of Our Rebuilt Engines:

Superior Quality Assurance: Each engine is rebuilt with precision using state-of-the-art equipment and high-quality parts to ensure it meets original manufacturer specifications.

Wide Selection: We provide an extensive range of rebuilt engines for all major automotive brands and models, ensuring you find the perfect match for your vehicle’s specific needs.

Cost-Effective Performance: Enjoy the benefits of a like-new engine at a fraction of the cost. Our rebuilt engines offer a budget-friendly alternative without compromising on quality or performance.

Dedicated Customer Support: Our team of engine experts is committed to providing exceptional service. We are here to guide you through the selection process and answer any questions you may have.

Efficient Delivery: Leveraging multiple distribution centers, we ensure swift and reliable delivery nationwide. Your rebuilt engine will arrive ready for installation, minimizing downtime and getting you back on the road faster.

Explore Top-Tier Remanufactured Transmissions at Fraser Engines and Transmissions

Revitalize your vehicle with a remanufactured transmission from Fraser Engines and Transmissions. Our remanufactured transmissions are meticulously restored to their original factory specifications by our team of skilled technicians. Each unit is disassembled, cleaned, inspected, and rebuilt using the highest quality replacement parts, ensuring enhanced durability and performance.

Why Choose Fraser Engines and Transmissions for Your Remanufactured Transmission?

Exceptional Quality: Every remanufactured transmission is rebuilt ABOVE OEM standards, incorporating the latest updates and improvements over the original design to increase reliability and longevity.

Extensive Inventory: We offer a wide array of remanufactured transmissions for various makes and models, ensuring a perfect fit and optimal functionality for your specific vehicle.

Affordable Solutions: Our remanufactured transmissions provide a cost-effective alternative to buying new, offering superior performance without the hefty price tag.

Expert Assistance: Our knowledgeable staff is dedicated to supporting you from the moment you inquire about a remanufactured transmission to the completion of your installation, ensuring a smooth and informed purchasing experience.

Quick Shipping: With facilities strategically located across the nation, we guarantee fast delivery times, minimizing downtime and getting you back on the road sooner.

Check Out Our Remanufactured Transmissions Today

Browse our selection of high-quality remanufactured transmissions. Trust in Fraser Engines and Transmissions to deliver not just a product, but a commitment to quality and customer satisfaction that revives and enhances your vehicle’s performance. Reach out to us today for personalized service and to find the transmission that best meets your needs.

WHY CONSIDER PURCHASING REMANUFACTURED ENGINES?

Considering purchasing a remanufactured engine is a wise decision for several reasons, each contributing to a mix of cost-effectiveness, reliability, environmental responsibility, and performance:

Cost Savings: Remanufactured engines are significantly less expensive than their new counterparts. This price difference makes them a budget-friendly option for those looking to extend the life of their vehicle without the financial burden of buying a brand-new engine.

High Quality and Reliability: Remanufactured engines undergo a thorough rebuilding process where they are disassembled, cleaned, inspected, and repaired to meet original manufacturer specifications. Worn or defective parts are replaced with new or refurbished components, which can often include updates that address the original design flaws, thereby increasing the engine’s reliability and performance.

Warranty and Support: Like new engines, remanufactured engines often come with warranties that provide additional peace of mind. This warranty coverage can rival or even exceed that offered with new engines, depending on the manufacturer or company providing the remanufacturing.

Environmental Benefits: Opting for a remanufactured engine is an environmentally friendly choice. The process of remanufacturing uses fewer new materials and expends less energy than building a completely new engine, reducing waste and energy use. It also helps keep engines out of landfills by giving them new life.

Availability: Remanufactured engines are readily available across a broad range of makes and models, which can be especially beneficial for older or discontinued vehicle models for which new engines may no longer be produced.

Quick Turnaround: Because remanufactured engines are built from existing engines, they can often be prepared and shipped quicker than a new engine, which may need to be manufactured from scratch.

Enhanced Performance: Since remanufactured engines are built to original specs, they often come with updates and modifications that improve performance. This ensures they run more efficiently and may even offer better fuel economy than before.

For vehicle owners who need a reliable engine replacement solution without the high cost, or for those who wish to make an environmentally responsible choice, remanufactured engines provide a compelling option that balances quality, affordability, and sustainability.

WHAT IS THE DIFFERENCE BETWEEN A RE-MANUFACTURED ENGINE AND A REBUILT ENGINE?

A remanufactured engine is one that has been disassembled, cleaned, repaired, and rebuilt to meet original manufacturer’s specifications. During the remanufacturing process, all worn, damaged or failed components are replaced with new or re-machined parts, and the engine is rigorously tested to ensure optimal performance. The remanufactured engine is essentially restored to its original condition, providing the same level of performance, longevity, and reliability as a brand new engine. A rebuilt engine, on the other hand, typically involves replacing only the failed or damaged components in an engine and re-assembling it.

Rebuilt engines may not undergo the same rigorous testing and quality control processes as a remanufactured engine and may be assembled with used or aftermarket parts rather than new OEM parts. While both remanufactured and rebuilt engines can offer a cost-effective solution compared to buying a brand new engine, there are some key differences. Remanufactured engines are generally of higher quality and reliability compared to rebuilt engines. They also tend to come with better warranties, often providing extra peace of mind to customers. Ultimately, the best option depends on the specific needs of the customer and their budget.

ENGINES FOR SALE

Buick Re-Manufactured Engines

Cadillac Re-Manufactured Engines

Chevrolet Re-Manufactured Engines

Chrysler Re-Manufactured Engines

Dodge Re-Manufactured Engines

Ford Re-Manufactured Engines

GMC Re-Manufactured Engines

Jeep Re-Manufactured Engines

Lincoln Re-Manufactured Engines

Mercury Re-Manufactured Engines

Oldsmobile Re-Manufactured Engines

Pontiac Re-Manufactured Engines

Infiniti Re-Manufactured Engines

Lexus Re-Manufactured Engines

Mazda Re-Manufactured Engines

Nissan Re-Manufactured Engines

Saab Re-Manufactured Engines

Saturn Re-Manufactured Engines

Honda Re-Manufactured Engines

Scion Re-Manufactured Engines

Subaru Re-Manufactured Engines

Toyota Re-Manufactured Engines

Volvo Re-Manufactured Engines

TRANSMISSIONS FOR SALE

Buick Re-Manufactured Transmissions

Cadillac Re-Manufactured Transmissions

Chevrolet Re-Manufactured Transmissions

Chrysler Re-Manufactured Transmissions

Dodge Re-Manufactured Transmissions

Ford Re-Manufactured Transmissions

GMC Re-Manufactured Transmissions

Jeep Re-Manufactured Transmissions

Lincoln Re-Manufactured Transmissions

Mercury Re-Manufactured Transmissions

Oldsmobile Re-Manufactured Transmissions

Pontiac Re-Manufactured Transmissions

Infiniti Re-Manufactured Transmissions

Lexus Re-Manufactured Transmissions

Mazda Re-Manufactured Transmissions

Nissan Re-Manufactured Transmissions

Saab Re-Manufactured Transmissions

Saturn Re-Manufactured Transmissions

Honda Re-Manufactured Transmissions

Scion Re-Manufactured Transmissions

Subaru Re-Manufactured Transmissions

Toyota Re-Manufactured Transmissions

Volvo Re-Manufactured Transmissions

NOTE: All Orders completed, then cancelled, incur a 10% processing fee.