FAST FACTS Vol. 1, Issue 10 – Doc Brown’s DeLorean

The 88-mile-per-hour stainless-steel hero of the Back To The Future movies How a movie franchise single-handedly etched DeLorean into the history book of cool cars

But, are you prepared to get your new baby properly installed? You’ve got a certified mechanic with a strong track record? Super! But just because you’re using a certified mechanic to install your Fraser Remanufactured Engine, is no excuse not to be educated. This Fraser Essential Engine Installation Checklist highlights the items to be addressed when replacing an engine. NOTE: Not every installer will do everything on this checklist. It is up to you if you sense they are being evasive or generally annoyed with your questions. There is nothing on this list that a true professional would shrug off. After all, it is your car and your money.

The installer should…

The installer may consider completely replacing the following items at the time of the engine installation, depending on their condition and age. They may be included in the price quoted to you, but often they are charged as an additional line item:

Consumable items are needed at the time of installation, which may be an additional, (non-included), charge to you, so check with your installer:

*Even though the oil in your new engine needs to be changed after the first 500 miles, and then again after the first 1,000 miles, Fraser highly recommends using 100% synthetic oil for the entire life of your engine. The enhanced protection of synthetic oil far outweighs the expense.

On the topic of the break-in period. This is not a joke, Your newly-rebuilt engine needs time to hone, harden, and acclimate internal parts. With a new rebuild, fine pieces of metal and debris can collect in the oil, to avoid any issues CHANGE THE OIL as recommended in the break-in instructions. You should also check the oil for possible impending break-in issues. The most obvious issues indicating there may be a forthcoming problem are burning oil and excessive debris in the oil pan.

Also, check your fluid levels at least once a week for the first few months, and correct them as needed. Engine fluids can be absorbed as they work themselves into the internal tubes and channels.

Also, check your fluid levels at least once a week for the first few months, and correct them as needed. Engine fluids can be absorbed as they work themselves into the internal tubes and channels.

If you have excessive fluid loss of any kind, check with a mechanic immediately. This is most likely covered under your warranty, so don’t wait or brush it off.

When you start your car up, outside the garage, ready to drive off… DON’T. If the mechanic says they have not performed an initial, stationary break-in, you should do it yourself in the parking lot. Simply allow your engine to run for at least 20 minutes. Vary the RPMs of the engine from idle to halfway to the red line.

All of these steps allow your cam, lifters, rings, seals, and bearings time to “shake hands” properly.

Remember, do not over-rev your engine. The first 1,000 miles is not the time to race anyone, i.e. redline the RPMs.

You’ve made all the right decisions in buying a Fraser Engine Co. remanufactured engine and finding and communicating with a reputable garage for the surgery. Don’t blow it by blowing it.

We wish you the best motoring experience!

The 88-mile-per-hour stainless-steel hero of the Back To The Future movies How a movie franchise single-handedly etched DeLorean into the history book of cool cars

More than just a vehicle, the Jeep Wrangler is your ultimate companion for any adventure. The Wrangler, paired with dependable engines like the Jeep 3.8L

She’ll love you, possess you, and then destroy you. Enjoy this first installment of “Scary Cars”, our October series Set in 1978, Christine chronicles how a possessed

Hey there, classic car buffs and Ford enthusiasts! Fraser Engines here, and we’ve got a real treat for you today—a deep dive into the legendary

Issue 1 • Engine & Transmission Tip Welcome to Fraser Engine Company’s Under The Hood – A new resource for engine and transmission tips. Our

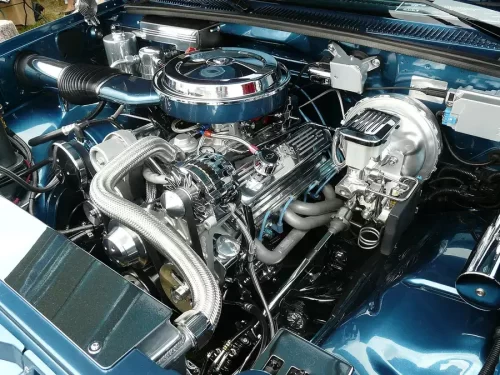

FRASER FRHP89 Chevy 350 Base Engine 390HP FRASER FRHP89 Chevy 350 Base Engine 390HP Fraser High Performance Unit $ 4199 00 Fully Refundable Core Deposit