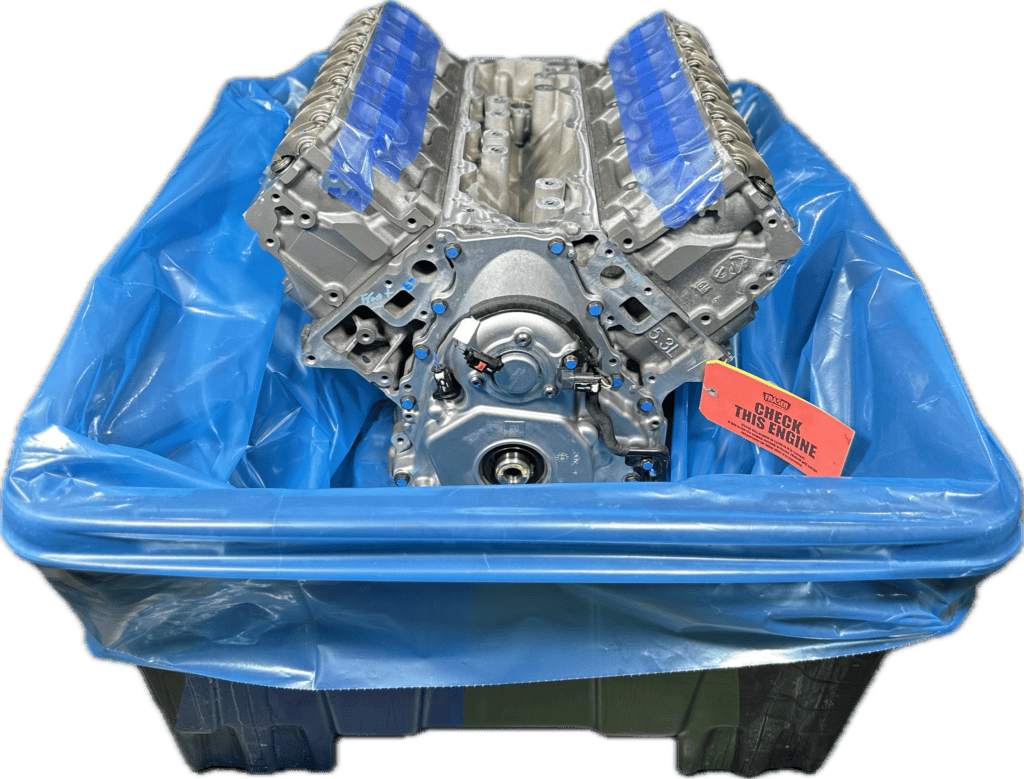

If you’re considering a replacement engine, let us tell you why a Fraser Advantage 5.3L engine is the best choice for your vehicle. At Fraser Engines, we focus on delivering engines that meet or even exceed original manufacturer standards, giving you the reliability, performance, and value you deserve.

Remanufactured to OEM Standards

Fraser Advantage engines are remanufactured, not just rebuilt. This means each engine goes through a thorough remanufacturing process that ensures it meets original equipment manufacturer (OEM) standards. We take extra care to inspect, clean, and replace components as needed, ensuring that your engine performs like new. We also upgrade any parts prone to wear or flaws, making sure your engine is more durable and reliable.

Comprehensive Quality Control

Every Fraser Advantage 5.3L engine undergoes extensive testing, from compression and leak testing to balancing the components to ensure smooth operation. We only work with certified technicians who pay close attention to every detail, giving you an engine that delivers optimal performance and peace of mind.

Industry-Leading Warranty

We stand behind our engines with an industry-leading warranty that covers parts and labor, so you can rest easy knowing that your investment is protected. Our warranties often extend up to 5 years or unlimited mileage, showing just how confident we are in the quality of our engines. Plus, if you ever need help, our supportive customer service team is here to assist you every step of the way.

Competitive Pricing

A Fraser Advantage 5.3L engine is a cost-effective solution compared to buying a brand-new vehicle or engine. By choosing Fraser, you get a high-quality engine at a fraction of the cost. And if budget is a concern, we also offer flexible financing options to make the process easier for you.

Upgraded Performance and Reliability

Our remanufactured 5.3L engines often feature performance upgrades and improved components, enhancing both reliability and power. This means fewer headaches for you, whether you’re towing, hauling, or simply commuting. You can trust the dependable power of a Fraser engine to keep you moving forward.

Easy Fitment and Convenience

The Fraser Advantage 5.3L engine is designed for seamless fitment with compatible Chevrolet, GMC, Cadillac, and Hummer models. We make sure that your replacement engine is ready to go, saving you time and effort during installation. Plus, with nationwide shipping, it’s easy to get your new engine delivered directly to your door.

Eco-Friendly Choice

Choosing a remanufactured Fraser engine is also an environmentally responsible decision. By remanufacturing, we reduce the need for new materials, helping to lower the overall carbon footprint and make a positive impact on the environment.

Proven Expertise

With decades of experience, Fraser Engines has built a solid reputation for delivering reliable, high-quality engines. We take pride in our work and have a long history of satisfied customers who appreciate the quality, support, and performance they get from Fraser. We’re here to make sure you get not only a great engine but also the after-sale support you need.

Make the Smart Choice

Choosing a Fraser Advantage 5.3L engine means you’re getting more than just a replacement—you’re getting a dependable upgrade backed by a leading warranty and the confidence of our support. Ready to bring your vehicle back to life? Trust in Fraser, and drive with peace of mind.

The 5.3L Gen IV Vortec (GEN III Fraser) engine, used by GM from 2010 to 2014, is a robust and versatile V8 engine that has been featured across a wide range of GM vehicles, particularly trucks and SUVs. Known for its balance of power, efficiency, and reliability, this engine came in several versions, including LC9, LY5, LMG, and LH9. Here is a detailed breakdown of the features, specifications, and key characteristics of the 5.3L Gen IV Vortec engine from this period.

Engine Overview

Displacement: 5.3 liters (5328 cc)

Configuration: V8, 90-degree layout

Block Material: Cast iron (LY5, LMG) or aluminum (LC9, LH9)

Head Material: Aluminum

Bore x Stroke: 3.78 in (96 mm) x 3.62 in (92 mm)

Compression Ratio: 9.9:1 (varies slightly depending on specific version)

Valvetrain: Overhead valve (OHV), 2 valves per cylinder (16 valves total)

Technical Features

Fuel System: Sequential Multi-Port Fuel Injection (MPFI)

Ignition System: Coil-on-plug ignition system

Variable Valve Timing (VVT): All versions of the 5.3L Gen IV Vortec engine from this period were equipped with VVT, which optimizes valve timing for better performance and fuel efficiency.

Active Fuel Management (AFM): The LC9, LMG, and LH9 versions featured AFM, which deactivates four of the eight cylinders under light load conditions to improve fuel economy.

Fuel Compatibility: The LC9 and LMG versions were flex-fuel capable, meaning they could run on gasoline or a blend of up to 85% ethanol (E85).

Performance

Horsepower: 315-326 hp at 5200 rpm (varies depending on the application and version)

Torque: 335-348 lb-ft at 4000 rpm (varies depending on the application and version)

Engine Management: Controlled by GM’s Powertrain Control Module (PCM), which adjusts fuel, spark, and air delivery to optimize performance and efficiency.

Design and Construction

Block and Heads: The engine block material depends on the version—cast iron for the LY5 and LMG for strength and durability, and aluminum for the LC9 and LH9 to reduce weight and improve efficiency. The cylinder heads are made of aluminum across all versions, providing good heat dissipation and contributing to overall weight reduction.

Valvetrain and Camshaft: The cam-in-block design uses a single camshaft that operates the pushrods to control the timing of the intake and exhaust valves. The use of Variable Valve Timing (VVT) enhances performance by adjusting the camshaft timing based on driving conditions.

Pistons and Connecting Rods: The pistons are made from hypereutectic aluminum alloy for better durability, while the connecting rods are made of powdered metal, providing strength and reliability under high-stress conditions.

Features and Technologies

Active Fuel Management (AFM): This technology is present in the LC9, LMG, and LH9 versions and allows the engine to deactivate half of its cylinders when full power is not needed, effectively turning the V8 into a V4. This improves fuel efficiency without sacrificing performance when power is required.

Flex-Fuel Capability: The LC9 and LMG versions are flex-fuel capable, meaning they can operate on either regular gasoline or E85 ethanol. This gives the owner more fueling options and can contribute to lower emissions and reduced fuel costs when E85 is available.

Variable Valve Timing (VVT): VVT is a feature across all 5.3L Gen IV engines, allowing the camshaft timing to be adjusted dynamically, optimizing the engine’s performance for different driving situations—whether for more power or better fuel efficiency.

Applications

The 5.3L Gen IV Vortec engine was used across a variety of GM vehicles between 2010 and 2014, particularly in full-size trucks and SUVs. Below are some of the vehicles that used this engine:

Chevrolet Silverado 1500 (2010-2014) – LC9, LMG, LY5

Chevrolet Avalanche (2010-2013) – LC9

Chevrolet Suburban 1500 (2010-2014) – LC9, LMG

Chevrolet Tahoe (2010-2014) – LC9, LMG

Chevrolet Express 1500 (2010-2014) – LMG

GMC Sierra 1500 (2010-2014) – LC9, LMG, LY5

GMC Yukon (2010-2014) – LC9, LMG

GMC Yukon XL 1500 (2010-2014) – LC9, LMG

Cadillac Escalade (2010-2014) – LC9

Chevrolet Colorado (2010-2012) – LH9

Hummer H3 (2010) – LH9

Fuel and Efficiency

Flex-Fuel Capability: The LC9 and LMG versions are capable of running on E85 ethanol, providing a more environmentally friendly option compared to regular gasoline. Flex-fuel capability allows these engines to reduce emissions and offer potential fuel cost savings.

Fuel Efficiency: The inclusion of Active Fuel Management (AFM) in the LC9, LMG, and LH9 engines helps improve fuel economy by deactivating half of the cylinders when cruising or under light load, effectively reducing fuel consumption.

Reliability and Maintenance

Durability: The cast iron block versions (LY5, LMG) are known for their durability, making them ideal for heavy-duty applications. The aluminum block versions (LC9, LH9) offer a good balance of strength and weight reduction, contributing to better efficiency.

Common Issues: Some common issues with the 5.3L Gen IV engine include oil consumption, particularly in engines with Active Fuel Management (AFM). Regular maintenance, such as timely oil changes and keeping the AFM system clean, can help mitigate these issues.

Maintenance Requirements: Routine maintenance, including oil changes, spark plug replacements, and coolant flushes, is essential for keeping the engine running smoothly. The coil-on-plug ignition system also simplifies maintenance by eliminating traditional spark plug wires.

STEP 1) ENGINE BLOCK DISASSEMBLY

Our journey begins with a thorough visual inspection of each engine block for casting defects. We meticulously disassemble the components, inspecting each part for damage and identifying the cause of failure. We remove oil and water passage plugs to guarantee optimal results during thermal cleaning. We select only premium castings for our marine blocks, insisting on replacements in all salt-water applications. For high-performance engines, we utilize premium cores, never employing repaired castings or sleeved blocks, preserving the authenticity of your classic car’s original block casting with our skilled technicians’ craftsmanship.

STEP 2) ENGINE BLOCK THERMAL CLEANING

We elevate engine parts to a new level of clean with our thermal cleaning system. This process evenly distributes heat throughout the chamber, avoiding overheating or warping. Components are heated in an oxygen-deficient atmosphere, decomposing combustible hydrocarbons and leaving parts dry. We use the Ace RKE 230 oven exclusively for cast iron blocks, ensuring ash residue is effortlessly removed in the subsequent stainless steel shot blasting phase.

STEP 3) ENGINE BLOCK SHOT BLASTING

Our shot-blasting method employs stainless steel shot to remove surface contamination like rust, creating a smoother finish. This step is vital for detecting surface and subsurface defects during quality inspection. The peening process imparts compression strength to the metal, preparing it for a preliminary defect inspection.

STEP 4) ENGINE BLOCK MAGNAFLUXING

We use magnetic particle inspection to detect cracks and imperfections in ferrous engine parts, ensuring the highest quality for our cast iron blocks. Before proceeding to aluminum blocks, we explain their specific cleaning, testing, and defect checking processes.

STEP 5) ENGINE BLOCK HIGH PRESSURE WASH

Aluminum engine blocks first encounter our AXE SW20 OS spray cleaning system, which removes all foreign material with its powerful spraying action and multi-integrated nozzles. This step is crucial for a thorough inspection.

STEP 6) ENGINE BLOCK SONIC CLEANING

We use ultrasonic cleaning for aluminum blocks, known as the benchmark in cleanliness. This method reaches inaccessible areas, breaking the bonds that hold small particles to surfaces. Post-cleaning, the block undergoes pressure testing.

STEP 7) ENGINE BLOCK PRESSURE TESTING

We employ the Delta Pressure tester to double-check for pinholes after magnafluxing and dye testing, ensuring the integrity of all castings used in our products.

STEP 8) ENGINE BLOCK PREPARATION

After a complete visual inspection, we repair minor casting defects, remove broken bolts, tap threads, and perform gasket surface repairs to minimize stock removal.

STEP 9) ENGINE BLOCK MACHINING

We use the RMC CNC V40 enclosed machining center for precise and versatile machining. This computerized machine measures and levels blocks, measures deck heights & cylinder bore sizes, eliminating operator error. Our machine determines Ra finish based on block type and gasket used, utilizing CBN cutters and checking surface finish with the Mitutoyo SJ-301.

STEP 10) ENGINE BLOCK ROD RECONDITIONING

The Sunnen LBB-1600 Hone, measuring accuracy within .0001″, is our choice for precision rod reconditioning and pin fitting, ensuring honed bores equal to or better than new rods. High-performance engines are fitted with ARP high-strength bolts and nuts prior to this step.

STEP 11) ENGINE BLOCK HONING

We are the first to use Rottler’s newest cylinder honing machine, ensuring the most accurate honing with cylinders finishing within .0001″ roundness and straightness. This machine continuously analyzes and corrects the bore, maintaining evolving engine designs’ critical oil clearances and machining tolerances.

STEP 12) ENGINE BLOCK HIGH PRESSURE WASH

After precise machining, our blocks undergo a second high-pressure wash cycle, ensuring absolute cleanliness for final assembly.

STEP 13) ENGINE BLOCK SONIC CLEANING

We ultrasonically clean all parts prior to assembly, ensuring the ultimate cleanliness level. This method reaches every surface and internal area, providing the cleaning force required for the most stringent standards.

STEP 14) ENGINE BLOCK ASSEMBLY

Each assembler at Fraser Engines conducts a thorough visual inspection and measures parts for proper size. We fit blocks with new cam bearings, oil restrictors, relief valves, new water and oil plugs, and more. Cylinder heads are installed with new bolts and gaskets, and each cylinder’s seal integrity is checked. The final inspection by our assembly manager ensures the highest quality for your remanufactured engine.

Fraser Engines is committed to delivering engines of exceptional quality and performance. Our rigorous, detailed remanufacturing process ensures every engine we deliver meets our high standards and exceeds your expectations.

Use conventional or break-in oil (non-synthetic) for the first 600 miles of operation. Do not drive for long periods at any single speed, always vary your speed. Do not tow a trailer or put other heavy loads on the vehicle. Check the engine oil and coolant levels daily.

At 600 Miles change the engine oil and filter using conventional (non-synthetic) oil. Check fuel and ignition settings; adjust valves (where applicable).

After the first 5,000 of service synthetic engine oil may be used. Follow your vehicle owner’s manual for service intervals.

Engine Block

Engine Block