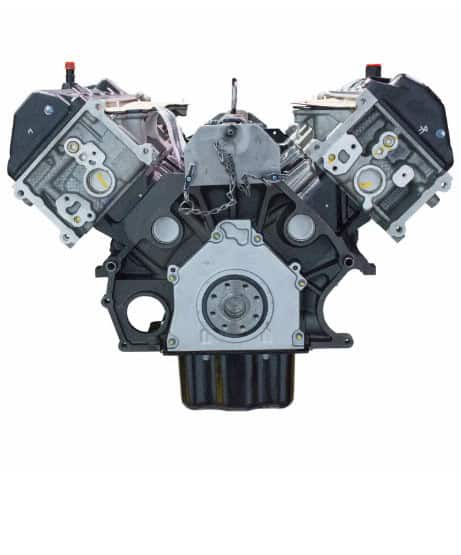

The 5.4L Triton engine is a flagship product at Fraser, renowned not just for its sales but for its performance over the past decade. We uphold the highest standards of quality and integrity, ensuring we never compromise on the work we deliver. Although the 5.4L Triton is known for certain issues, like cam phaser and oil pump problems, we at Fraser Engines have proactively addressed and rectified these concerns. This commitment to improvement and reliability is why it remains our top seller year after year.

Fraser Engines takes the 5.4L 3 Valve Triton Engine to new levels of durability and performance, addressing common issues with precision and advanced engineering. Our comprehensive updates ensure that every engine exceeds OEM standards, providing peace of mind and enhanced functionality for all applications.

Solutions for Spark Plug Issues Understanding the critical nature of the spark plug issues, Fraser Engines reinforces the engine heads with welding to create a new, more robust surface. We then meticulously drill and tap to add more threads than the original factory engine, effectively resolving the notorious problem of spark plugs blowing out and thread issues.

Upgraded Timing Components for Premium Performance To eliminate timing failures, we incorporate the latest OEM timing components, including upgraded tensioners and guides. This upgrade is designed to prevent chain slap and failure, ensuring smooth operation and extended engine life.

Valve Train Redesign Every engine benefits from entirely new valves, locks, guides, seats, rockers, and lifters. This comprehensive overhaul addresses any potential valve failure and significantly reduces valve train noise, guaranteeing a quiet and reliable performance.

High-Flow / High Volume MELLINGS M-360 Oil Pump Installation An updated high-flow oil pump is installed in each engine to meet the lubrication demands of critical components, especially at the top end. This ensures constant lubrication and protection under all operating conditions.

Advanced Piston Technology We equip our engines with hypereutectic graphite-coated pistons, designed for a tighter fit and reduced wear over the engine’s lifespan. This technology not only enhances performance but also prolongs the durability of the engine.

Multi-Layer Steel Head Gaskets for Superior Sealing To combat cylinder head gasket failures, Fraser Engines installs new OEM multi-layer steel head gaskets. These gaskets are specifically chosen for their ability to withstand the high operating temperatures of the 5.4L Triton engine, providing exceptional sealing and heat resistance.

✦Quality checks at every phase of production

✦Best in class leak detection testing system

✦Surface finish to OE Specifications for performance and durability augmentation

✦Dyno testing to ensure correct compression, oil flow, oil pressure, torque to turn and variable cam phaser operation where applicable

✦Industry Leading In-Process Machining, In-Process Testing and Monitoring

✦Assembled with Manufacturing Execution System for continuous monitoring and recording of all torque and in process inspection results

✦100% lifter bore diameter inspection to help ensure OE level lifter to lifter bore clearance and ensure minimal valve train noise

✦100% inspection of piston clearance to allow for tighter piston-to-bore clearance to prevent piston slap and oil consumption

✦Cylinder heads are 100% pressure tested after installation to identify cracks or sealing issues

✦Updated High Volume Oil Pump with a cast iron backing plate and higher pressure relief valve spring for improved oil pressure

✦Use of High Integrity Components

✦100% use of PTFE coated pistons to prevent scuffing and wear

✦In Process piston circlip validation

✦Use of ALL NEW rod and head bolts to reduce potential fatigue and ensure long engine life

✦CNC cut Valve seats for improved sealing & run-out, allowing for longer valve & seat