1-Year No-Fault Warranty

$99.00

- One-time free replacement, no matter the cause of failure.

- Unlimited miles during the 1-year term.

- Labor covered at $50.00/hr (Mitchell or AllData book time).

MANUFACTURER: VEGE Engines

🚚 Normally Delivers in 2-3 Business Days

Fraser Engines has identified that many Active Fuel Management (AFM) lifter failures are not due to defective parts, but rather to issues with oil pressure or oil control within the system. Our testing has shown that a majority of returned AFM lifters function properly when evaluated under correct conditions.

The AFM system operates within a normal oil pressure range of 27 PSI to 66 PSI. Activation and deactivation of AFM lifters are controlled by the Valve Lifter Oil Manifold (VLOM), which directs pressurized oil to the AFM lifters when cylinder deactivation is commanded and stops that flow to reactivate the cylinders.

In several warranty cases, AFM lifters have been found stuck in a compressed position. This condition is often caused by the VLOM commanding activation or deactivation at the wrong point in the camshaft rotation — such as during the ramp or at the lobe peak — rather than a fault within the lifter itself.

Installer Responsibility: When replacing AFM components, the installer must replace the OEM valve lifter oil manifold (VLOM) filter located under the oil pressure sender. The VLOM assembly should also be tested for proper operation or replaced as necessary.

Warranty Disclaimer: Any failure resulting from improper VLOM operation, restricted oil passages, or a contaminated or untested VLOM assembly will not be covered under warranty.

🔧 Premium Installation Kit – $250.00

1-Year No-Fault Warranty

$99.00

2-Year No-Fault Warranty

$199.00

3-Year No-Fault Warranty

$299.00

4-Year No-Fault Warranty

$399.00

5-Year No-Fault Elite

$499.00

Labor reimbursement uses published Mitchell or AllData times. One-time replacement applies per covered unit during the elected term.

The Standard Option engine from Fraser Engines is built to original OEM specifications, similar to what you’d find from most online retailers (e.g., Powertrain, AutoZone, Advance Auto Parts, etc.). This option is ideal for those needing a quick solution or simply looking for a reliable engine to get their vehicle back on the road. If you’re seeking an upgraded version of this engine, we highly recommend exploring the Fraser Advantage build.

Not ready to buy just yet? No problem — click the button below to lock in the current sale price for the next 30 days. Even if the price goes up, your locked-in rate stays the same. It’s a simple way to secure today’s savings while you take time to decide.

| Year(s) | Make | Model | Engine Code (RPO) | Notes |

|---|---|---|---|---|

| 2007–2008 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L92 | Vortec 6200; ~403 hp |

| 2007–2008 | GMC | Yukon Denali / Yukon XL Denali | L92 | Vortec 6200 |

| 2007–2008 | GMC | Sierra 1500 Denali | L92 | Denali package |

| 2008 | Chevrolet | Tahoe LTZ | L92 | Limited 6.2L option |

| 2008–2009 | Hummer | H2 / H2 SUT | L92 | 6.2L upgrade |

| 2009 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L9H | FlexFuel 6.2L |

| 2009 | GMC | Yukon Denali / Yukon XL Denali | L9H | FlexFuel 6.2L |

| 2009–2013 | GMC | Sierra 1500 (incl. Denali) | L9H | 403 hp |

| 2010–2013 | Chevrolet | Silverado 1500 | L9H | Optional 6.2L |

| 2010–2013 | Cadillac | Escalade / ESV / EXT | L94 | AFM + VVT, FlexFuel |

| 2010–2013 | GMC | Yukon Denali / Yukon XL Denali | L94 | AFM + VVT, FlexFuel |

| 2008–2013 | Chevrolet | Corvette (C6) / Grand Sport | LS3 | 430–436 hp |

| 2010–2013 | Chevrolet | Camaro SS (Manual) | LS3 | Gen IV 6.2L N/A |

| 2010–2013 | Chevrolet | Camaro SS (Automatic) | L99 | AFM-equipped 6.2L |

| 2009 | Pontiac | G8 GXP | LS3 | One-year only |

| 2009–2013 | Chevrolet | Corvette ZR1 | LS9 | 6.2L supercharged |

| 2009–2013 | Cadillac | CTS-V | LSA | 6.2L supercharged |

| 2012–2013 | Chevrolet | Camaro ZL1 | LSA | 6.2L supercharged |

🇺🇸 MANUFACTURER: NORTH AMERICAN AUTOMOTIVE ENGINE REBUILDERS

🚚 Normally Delivers in 2-3 Business Days

Fraser Engines has identified that many Active Fuel Management (AFM) lifter failures are not due to defective parts, but rather to issues with oil pressure or oil control within the system. Our testing has shown that a majority of returned AFM lifters function properly when evaluated under correct conditions.

The AFM system operates within a normal oil pressure range of 27 PSI to 66 PSI. Activation and deactivation of AFM lifters are controlled by the Valve Lifter Oil Manifold (VLOM), which directs pressurized oil to the AFM lifters when cylinder deactivation is commanded and stops that flow to reactivate the cylinders.

In several warranty cases, AFM lifters have been found stuck in a compressed position. This condition is often caused by the VLOM commanding activation or deactivation at the wrong point in the camshaft rotation — such as during the ramp or at the lobe peak — rather than a fault within the lifter itself.

Installer Responsibility: When replacing AFM components, the installer must replace the OEM valve lifter oil manifold (VLOM) filter located under the oil pressure sender. The VLOM assembly should also be tested for proper operation or replaced as necessary.

Warranty Disclaimer: Any failure resulting from improper VLOM operation, restricted oil passages, or a contaminated or untested VLOM assembly will not be covered under warranty.

🔧 Premium Installation Kit – $250.00

1-Year No-Fault Warranty

$99.00

Included at no charge with any Fraser Advantage™ engine purchase.

2-Year No-Fault Warranty

$199.00

3-Year No-Fault Warranty

$299.00

4-Year No-Fault Warranty

$399.00

5-Year No-Fault Elite

$499.00

Labor reimbursement uses published Mitchell or AllData times with ASE-certified shop documentation. One-time replacement applies per covered unit during the elected term.

The Fraser Advantage™ engine is our highest-spec remanufactured option. Each unit is remanufactured to Fraser Advantage standards by approved facilities, with all applicable OEM Technical Service Bulletin (TSB) updates applied to address known factory concerns. Using premium components and precise machining, every engine is validated through comprehensive pre-shipment testing. Fraser Advantage is engineered for customers who prioritize long-term reliability and low ownership risk—delivering confident, best-in-class performance while proactively mitigating common issues found in original configurations.

Not ready to buy just yet? No problem — click the button below to lock in the current sale price for the next 30 days. Even if the price goes up, your locked-in rate stays the same. It’s a simple way to secure today’s savings while you take time to decide.

| Year(s) | Make | Model | Engine Code (RPO) | Notes |

|---|---|---|---|---|

| 2007–2008 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L92 | Vortec 6200; ~403 hp |

| 2007–2008 | GMC | Yukon Denali / Yukon XL Denali | L92 | Vortec 6200 |

| 2007–2008 | GMC | Sierra 1500 Denali | L92 | Denali package |

| 2008 | Chevrolet | Tahoe LTZ | L92 | Limited 6.2L option |

| 2008–2009 | Hummer | H2 / H2 SUT | L92 | 6.2L upgrade |

| 2009 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L9H | FlexFuel 6.2L |

| 2009 | GMC | Yukon Denali / Yukon XL Denali | L9H | FlexFuel 6.2L |

| 2009–2013 | GMC | Sierra 1500 (incl. Denali) | L9H | 403 hp |

| 2010–2013 | Chevrolet | Silverado 1500 | L9H | Optional 6.2L |

| 2010–2013 | Cadillac | Escalade / ESV / EXT | L94 | AFM + VVT, FlexFuel |

| 2010–2013 | GMC | Yukon Denali / Yukon XL Denali | L94 | AFM + VVT, FlexFuel |

| 2008–2013 | Chevrolet | Corvette (C6) / Grand Sport | LS3 | 430–436 hp |

| 2010–2013 | Chevrolet | Camaro SS (Manual) | LS3 | Gen IV 6.2L N/A |

| 2010–2013 | Chevrolet | Camaro SS (Automatic) | L99 | AFM-equipped 6.2L |

| 2009 | Pontiac | G8 GXP | LS3 | One-year only |

| 2009–2013 | Chevrolet | Corvette ZR1 | LS9 | 6.2L supercharged |

| 2009–2013 | Cadillac | CTS-V | LSA | 6.2L supercharged |

| 2012–2013 | Chevrolet | Camaro ZL1 | LSA | 6.2L supercharged |

🇺🇸 MANUFACTURER: PRMR ENGINES

🚚 Normally Delivers in 2-3 Business Days

🔧 Premium Installation Kit – $250.00

1-Year No-Fault Warranty

$99.00

Included at no charge with any Fraser Advantage™ engine purchase.

2-Year No-Fault Warranty

$199.00

3-Year No-Fault Warranty

$299.00

4-Year No-Fault Warranty

$399.00

5-Year No-Fault Elite

$499.00

Labor reimbursement uses published Mitchell or AllData times with ASE-certified shop documentation. One-time replacement applies per covered unit during the elected term.

A 6.2L DOD Delete Engine is a modified version of the original 6.2L engine in which the Displacement on Demand (DOD) system—also known as Active Fuel Management (AFM)—has been removed. This modification enhances the engine’s durability and reliability by eliminating the DOD system’s frequent activation and deactivation of cylinders, which can lead to premature wear of lifters, camshafts, and other components.

The 6.2L DOD Delete Engine is a popular choice for those seeking long-term reliability and performance without the drawbacks of the DOD system. It’s especially beneficial for high-mileage vehicles or engines subjected to demanding conditions. Fraser Engines incorporates critical updates to ensure optimal performance and reliability.

Not ready to buy just yet? No problem — click the button below to lock in the current sale price for the next 30 days. Even if the price goes up, your locked-in rate stays the same. It’s a simple way to secure today’s savings while you take time to decide.

| Year(s) | Make | Model | Engine Code (RPO) | Notes |

|---|---|---|---|---|

| 2007–2008 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L92 | Vortec 6200; ~403 hp |

| 2007–2008 | GMC | Yukon Denali / Yukon XL Denali | L92 | Vortec 6200 |

| 2007–2008 | GMC | Sierra 1500 Denali | L92 | Denali package |

| 2008 | Chevrolet | Tahoe LTZ | L92 | Limited 6.2L option |

| 2008–2009 | Hummer | H2 / H2 SUT | L92 | 6.2L upgrade |

| 2009 | Cadillac | Escalade / Escalade ESV / Escalade EXT | L9H | FlexFuel 6.2L |

| 2009 | GMC | Yukon Denali / Yukon XL Denali | L9H | FlexFuel 6.2L |

| 2009–2013 | GMC | Sierra 1500 (incl. Denali) | L9H | 403 hp |

| 2010–2013 | Chevrolet | Silverado 1500 | L9H | Optional 6.2L |

| 2010–2013 | Cadillac | Escalade / ESV / EXT | L94 | AFM + VVT, FlexFuel |

| 2010–2013 | GMC | Yukon Denali / Yukon XL Denali | L94 | AFM + VVT, FlexFuel |

| 2008–2013 | Chevrolet | Corvette (C6) / Grand Sport | LS3 | 430–436 hp |

| 2010–2013 | Chevrolet | Camaro SS (Manual) | LS3 | Gen IV 6.2L N/A |

| 2010–2013 | Chevrolet | Camaro SS (Automatic) | L99 | AFM-equipped 6.2L |

| 2009 | Pontiac | G8 GXP | LS3 | One-year only |

| 2009–2013 | Chevrolet | Corvette ZR1 | LS9 | 6.2L supercharged |

| 2009–2013 | Cadillac | CTS-V | LSA | 6.2L supercharged |

| 2012–2013 | Chevrolet | Camaro ZL1 | LSA | 6.2L supercharged |

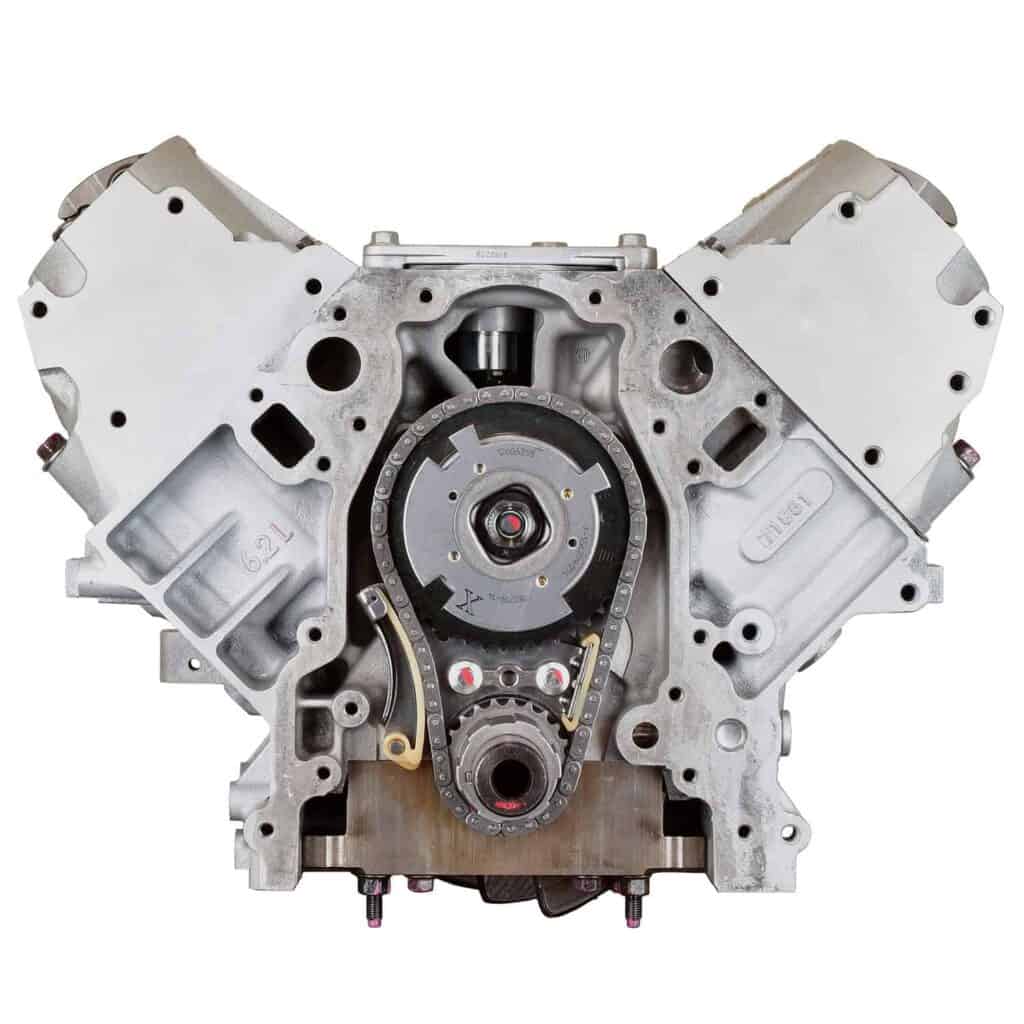

The 6.2L GM V8 engine, part of the Gen IV small-block family, is widely known for its power and performance in trucks, SUVs, and performance vehicles. While reliable, this engine has some common issues that Fraser Engines addresses through precision remanufacturing and key technical updates. These improvements enhance durability, performance, and overall reliability.

Upgraded Lifters and Camshaft

Cylinder Deactivation (AFM/DOD) Delete Option

Enhanced Cylinder Heads

Improved Piston and Ring Design

High-Performance Oil Pump

Reinforced Timing Chain Components

Carbon Build-Up Prevention

Improved Cooling System Components

Precision-Balanced Rotating Assembly

High-Quality Gaskets and Seals

Updated Valve Springs and Rocker Arms

Fraser Engines delivers remanufactured 6.2L GM engines (2007–2013) with critical updates that maximize performance and reliability. For more details or assistance, contact us today!

Fraser Engines is committed to delivering superior remanufactured 6.2L GM engines that stand out from the competition in quality, performance, and customer satisfaction. Here’s why choosing a Fraser Advantage 6.2L engine is the best decision for your vehicle:

Fraser addresses all known issues with the 6.2L GM engine, including:

These updates resolve the factory weaknesses that lead to premature failures, providing you with a more reliable engine.

Fraser Engines are rebuilt with high-quality materials and precision machining:

Every engine is built to meet or exceed OEM specifications, ensuring long-lasting performance.

Each Fraser 6.2L engine undergoes comprehensive testing to verify:

This ensures that your engine is ready to perform right out of the box.

Fraser offers flexibility to meet your needs:

Fraser Engines backs every 6.2L engine with a robust warranty, providing you peace of mind and confidence in your investment. Few competitors can match Fraser’s level of warranty coverage.

Fraser’s 6.2L engines are designed to fit seamlessly into a range of GM vehicles, including:

Each engine is tailored to perform at its best, whether for towing, hauling, or performance driving.

Fraser combines top-tier quality with competitive pricing, delivering the perfect balance of performance and affordability. With Fraser, you’re investing in long-term reliability and customer satisfaction.

Fraser’s team of skilled technicians and customer service professionals are here to assist you every step of the way:

When you choose a Fraser Advantage 6.2L engine, you’re not just buying a replacement engine—you’re investing in unmatched quality, performance, and reliability. Let Fraser Engines help you get back on the road with confidence.

Contact Fraser Engines today to experience the Fraser Advantage!

Our journey begins with a thorough visual inspection of each engine block for casting defects. We meticulously disassemble the components, inspecting each part for damage and identifying the cause of failure. We remove oil and water passage plugs to guarantee optimal results during thermal cleaning. We select only premium castings for our marine blocks, insisting on replacements in all salt-water applications. For high-performance engines, we utilize premium cores, never employing repaired castings or sleeved blocks, preserving the authenticity of your classic car’s original block casting with our skilled technicians’ craftsmanship.

We elevate engine parts to a new level of clean with our thermal cleaning system. This process evenly distributes heat throughout the chamber, avoiding overheating or warping. Components are heated in an oxygen-deficient atmosphere, decomposing combustible hydrocarbons and leaving parts dry. We use the Ace RKE 230 oven exclusively for cast iron blocks, ensuring ash residue is effortlessly removed in the subsequent stainless steel shot blasting phase.

Our shot-blasting method employs stainless steel shot to remove surface contamination like rust, creating a smoother finish. This step is vital for detecting surface and subsurface defects during quality inspection. The peening process imparts compression strength to the metal, preparing it for a preliminary defect inspection.

We use magnetic particle inspection to detect cracks and imperfections in ferrous engine parts, ensuring the highest quality for our cast iron blocks. Before proceeding to aluminum blocks, we explain their specific cleaning, testing, and defect checking processes.

Aluminum engine blocks first encounter our AXE SW20 OS spray cleaning system, which removes all foreign material with its powerful spraying action and multi-integrated nozzles. This step is crucial for a thorough inspection.

We use ultrasonic cleaning for aluminum blocks, known as the benchmark in cleanliness. This method reaches inaccessible areas, breaking the bonds that hold small particles to surfaces. Post-cleaning, the block undergoes pressure testing.

We employ the Delta Pressure tester to double-check for pinholes after magnafluxing and dye testing, ensuring the integrity of all castings used in our products.

After a complete visual inspection, we repair minor casting defects, remove broken bolts, tap threads, and perform gasket surface repairs to minimize stock removal.

We use the RMC CNC V40 enclosed machining center for precise and versatile machining. This computerized machine measures and levels blocks, measures deck heights & cylinder bore sizes, eliminating operator error. Our machine determines Ra finish based on block type and gasket used, utilizing CBN cutters and checking surface finish with the Mitutoyo SJ-301.

The Sunnen LBB-1600 Hone, measuring accuracy within .0001″, is our choice for precision rod reconditioning and pin fitting, ensuring honed bores equal to or better than new rods. High-performance engines are fitted with ARP high-strength bolts and nuts prior to this step.

We are the first to use Rottler’s newest cylinder honing machine, ensuring the most accurate honing with cylinders finishing within .0001″ roundness and straightness. This machine continuously analyzes and corrects the bore, maintaining evolving engine designs’ critical oil clearances and machining tolerances.

After precise machining, our blocks undergo a second high-pressure wash cycle, ensuring absolute cleanliness for final assembly.

We ultrasonically clean all parts prior to assembly, ensuring the ultimate cleanliness level. This method reaches every surface and internal area, providing the cleaning force required for the most stringent standards.

Each assembler at Fraser Engines conducts a thorough visual inspection and measures parts for proper size. We fit blocks with new cam bearings, oil restrictors, relief valves, new water and oil plugs, and more. Cylinder heads are installed with new bolts and gaskets, and each cylinder’s seal integrity is checked. The final inspection by our assembly manager ensures the highest quality for your remanufactured engine.

Fraser Engines is committed to delivering engines of exceptional quality and performance. Our rigorous, detailed remanufacturing process ensures every engine we deliver meets our high standards and exceeds your expectations.

At Fraser Engines, we embrace cutting-edge technology to ensure that every engine we remanufacture meets the highest standards of quality and performance. A cornerstone of our state-of-the-art machinery is the ACF200 Cylinder Boring-Resurfacing Machine. This sophisticated equipment plays a pivotal role in our engine rebuilding process, allowing us to deliver products that consistently exceed expectations.

The ACF200 is renowned for its precision and versatility. Our skilled technicians utilize this machine’s advanced capabilities to perform intricate machining tasks with unmatched accuracy.

Incorporating the ACF200 into our remanufacturing process allows us to offer several distinct advantages:

Meticulous Cylinder Machining: Each engine’s cylinders are bored and honed to exact dimensions, ensuring optimal fit and function. This meticulous attention to detail is crucial for the engine’s performance and the vehicle’s overall efficiency.

Flawless Surface Finishing: Proper head gasket sealing is paramount in engine rebuilding. The ACF200 enables us to resurface engine blocks and cylinder heads to precise specifications, ensuring a perfect seal and reliable performance.

Assured Quality and Performance: With the ACF200’s precision, every engine remanufactured at Fraser Engines is a testament to our commitment to quality. We don’t just rebuild engines; we enhance them, setting new benchmarks for performance and reliability in the remanufacturing industry.

At Fraser Engines, we pride ourselves on being at the forefront of remanufacturing innovation, and our CNC Crankshaft Grinder stands as a testament to this commitment. As a leading remanufacturer, we boast the utilization of CNC Crank Grinders, a technology that sets us apart and reinforces our position as an industry pioneer in the United States.

Our CNC Crankshaft Grinder represents the pinnacle of modern engineering, bringing the precision of fully automated production processes, typically exclusive to OEM plants, into our remanufacturing workflow.

One-Chucking Complete Grinding: Designed for efficiency and excellence, the CNC Crankshaft Grinder performs complete grinding of crankshafts in a single chucking. This advanced approach ensures consistency and precision throughout the entire process.

Unmatched Precision and Quality: The machine’s capabilities extend far beyond the current industry standards, offering:

At Fraser Engines, we’re committed to innovation and excellence in every facet of our remanufacturing process. Our continuous pursuit of improvement and our investment in the latest technologies underscore this commitment. A shining example of our forward-thinking approach is the integration of state-of-the-art flame spray technology into our operations.

Recently, Fraser Engines has taken a significant leap forward by incorporating the latest flame spray machine into our remanufacturing facilities. Installed and fully operational since 2016, this technology marks a new era in our production capabilities.

Setting New Standards in Finish Quality: The flame spray machine elevates our ability to meet and exceed the finish requirements for engine block cylinder bores. With this technology, Fraser Engines effortlessly surpasses the industry benchmarks for remanufacturing current model year engines.

Unparalleled Precision and Durability: Flame spray technology allows us to apply coatings with unmatched precision and uniformity, ensuring each engine block’s durability and performance are maximized. This process not only enhances the quality of the finished product but also extends the lifespan of the engines we remanufacture.

The 6.2L GM V8 engine, part of the Gen IV small-block family, is renowned for its powerful performance, durability, and versatility. Originally designed to deliver high output and smooth operation, this engine was commonly found in GM trucks, SUVs, and performance cars between 2007 and 2013. Its combination of advanced engineering and robust construction makes it a favorite for both work and play.

Engine Type:

Displacement:

Performance:

Fuel System:

Compression Ratio:

Advanced Technology:

The 6.2L GM engine was used in a wide range of vehicles across GM’s lineup, including:

Trucks and SUVs:

Performance Cars:

While the 6.2L GM engine is robust, some common issues include:

The 6.2L V8 engine is part of GM’s Gen IV small-block family and is known for its robust performance, versatility, and reliability. Below are the detailed specifications:

Active Fuel Management (AFM/DOD):

Hydraulic Roller Camshaft:

High-Capacity Oil Pump:

Dual Knock Sensors:

The 6.2L GM engine is found in:

Use conventional or break-in oil (non-synthetic) for the first 600 miles of operation. Do not drive for long periods at any single speed, always vary your speed. Do not tow a trailer or put other heavy loads on the vehicle. Check the engine oil and coolant levels daily.

At 600 Miles change the engine oil and filter using conventional (non-synthetic) oil. Check fuel and ignition settings; adjust valves (where applicable).

Fraser Engines & Transmissions is your trusted partner for 6.2L GM engine remanufacturing, offering unmatched quality and performance. Our state-of-the-art remanufacturing process involves precision engineering and the use of high-grade materials, ensuring each engine surpasses original specifications for durability and reliability.

We back our remanufactured our 6.2L GM engines with an industry-leading warranty, reflecting our commitment to quality and customer satisfaction. This robust warranty coverage is our guarantee of reliability, offering you peace of mind with every purchase.

Our team of experts is dedicated to providing personalized consultation services, ensuring that your 6.2L GM engine selection is perfectly aligned with your vehicle’s performance requirements. We focus on understanding your needs to recommend the best engine solution, promising optimal performance and seamless integration.

Opting for a remanufactured 6.2L GM engine from Fraser Engines & Transmissions means choosing an upgrade that enhances your vehicle’s efficiency, power, and reliability. Explore our selection of premium remanufactured engines today and take the first step towards a superior driving experience.