TECH UPDATES

✦Quality checks at every phase of production

✦Best in class leak detection testing system

✦Surface finish to OE Specifications for performance and durability augmentation

✦Dyno testing to ensure correct compression, oil flow, oil pressure, torque to turn and variable cam phaser operation where applicable

✦Industry Leading In-Process Machining, In-Process Testing and Monitoring

✦Assembled with Manufacturing Execution System for continuous monitoring and recording of all torque and in process inspection results

✦100% lifter bore diameter inspection to help ensure OE level lifter to lifter bore clearance and ensure minimal valve train noise

✦100% inspection of piston clearance to allow for tighter piston-to-bore clearance to prevent piston slap and oil consumption

✦Cylinder heads are 100% pressure tested after installation to identify cracks or sealing issues

✦Updated High Volume Oil Pump with a cast iron backing plate and higher pressure relief valve spring for improved oil pressure

✦Use of High Integrity Components

✦100% use of PTFE coated pistons to prevent scuffing and wear

✦In Process piston circlip validation

✦Use of ALL NEW rod and head bolts to reduce potential fatigue and ensure long engine life

✦CNC cut Valve seats for improved sealing & run-out, allowing for longer valve & seat

Why Choose Fraser Advantage Over Standard Rebuilds?

When it comes to revitalizing your engine, the choice between a standard rebuild and the Fraser Advantage is the choice between ordinary and extraordinary. Here’s why you should elevate your driving experience with Fraser Advantage:

Precision Redefined:

- Fraser Advantage goes beyond industry standards, providing precision machining with tolerances as fine as .0001 of an inch. Your engine isn’t just rebuilt; it’s meticulously crafted to perfection, ensuring optimal performance.

Enhanced Durability:

- The Fraser Advantage includes decking of cylinder head(s) and block for optimal straightness, coupled with line boring and honing of crankshaft/camshaft tunnels. These enhancements reinforce critical components, providing durability that outlasts the ordinary.

Exclusive Valve Optimization:

- Cutting valve seats and valves to the proper degree is a Fraser Advantage exclusive. This precision work ensures superior valve functionality, setting your engine apart from the limitations of standard rebuilds.

Premium Component Selection:

- Fraser Advantage doesn’t compromise on quality. Enjoy the benefits of a ground and polished crankshaft, new or remanufactured camshaft(s), and a comprehensive replacement of main bearings, rod bearings, pistons, piston rings, lifters, pushrods, timing components, oil pump, and head bolts.

Comprehensive Gasket Overhaul:

- While standard rebuilds may offer basic gasket replacements, Fraser Advantage provides a complete internal gasket and seal overhaul. Every detail is considered, ensuring a comprehensive solution to keep your engine running seamlessly.

Tailored Finishing:

- Fraser Advantage ensures a hassle-free installation with finishing gaskets tailored to your specific application. This attention to detail completes the rebuild, providing a level of craftsmanship that transcends the ordinary.

In essence, Fraser Advantage is not just a rebuild; it’s a transformation. It’s a commitment to excellence, precision, and durability that goes beyond the standard. Choose Fraser Advantage for an engine that doesn’t just run – it roars with power, reliability, and an unrivaled level of craftsmanship. Elevate your driving experience – choose Fraser Advantage.

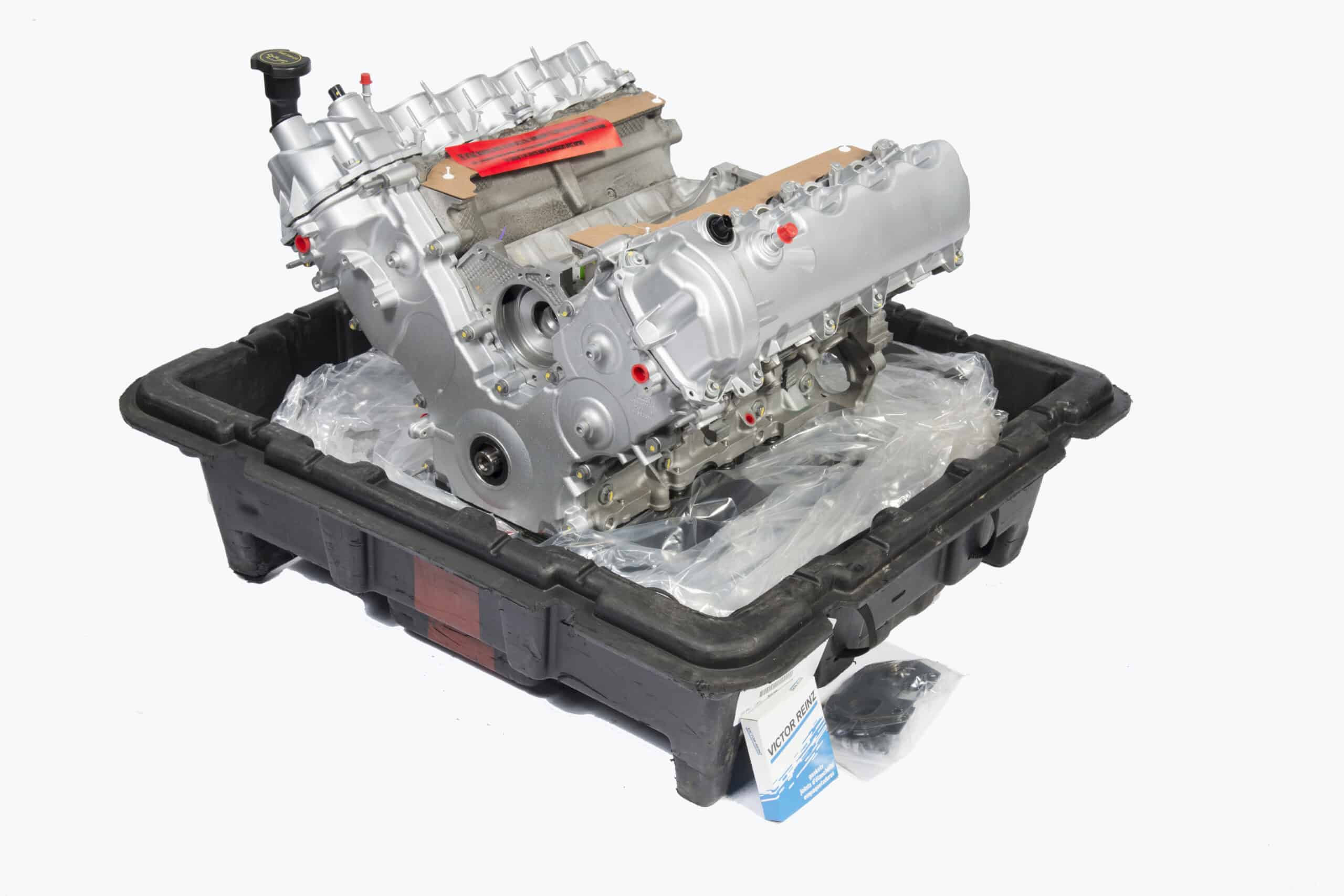

This remanufactured FORD 4.6L 3 valve engine includes the following enhancements from Fraser Engines:

- Bore and hone all cylinders to OEM clearances (We check all clearances within .0001 of inch),

- Decking cylinder head(s) and block for straightness,

- Cutting valve seats and valves to proper degree,

- Line boring/honing crankshaft/camshaft tunnels,

- Ground & polish crankshaft, new or remanufactured camshaft(s),

- New main bearings, rod bearings, pistons, piston rings, lifters, pushrods (if equipped), timing components, oil pump, head bolts,

- All new internal gaskets and seals.

- All finishing gaskets are included (MAY VARY PER APPLICATION).

FORD 4.6L 3 Valve Engines

The FORD 4.6L 3 Valve Engine 1991-2019 is a V8 engine designed and produced by Ford Motor Company.

The base engine consists of:

An all-aluminum engine block and cylinder head (in later models, a cast-iron block was also used)

Dual Overhead Camshafts (DOHC) or Single Overhead Camshafts (SOHC) depending on the valve configuration

Variable Valve Timing (VVT)

Sequential multi-port fuel injection

The engine specifications include:

- A displacement of 281 cubic inches (4,605 cubic centimeters)

- 3.55 in x 3.54 in (90.2 mm x 90 mm) or 3.55 in x 3.54 in (90.2 mm x 90.2 mm) cylinder bore and piston stroke depending on the valve configuration

- 9.4:1 or 10.8:1 compression ratio depending on the year and model

- 190 to 390 horsepower (142 to 291 kW) at 4,250 to 6,000 rpm depending on the year and model

- 260 to 410 lb-ft (353 to 556 Nm) of torque at 3,250 to 4,250 rpm depending on the year and model

The FORD 4.6L engine was first introduced in 1991 and was used in various Ford applications, including the Mustang, Crown Victoria, Town Car, Grand Marquis, F-150, and Expedition. The engine was also used in the Mercury Grand Marquis, Cougar, and Mountaineer, as well as in the Lincoln Town Car, Navigator, and Aviator.

The FORD 4.6L engine is renowned for its reliability and durability, with some models exceeding 300,000 miles with regular maintenance. The engine also offers good performance, with some models capable of reaching 0-60 mph in under 6 seconds. In 2005, the engine received an update, which included a switch from a cast-iron to an aluminum block, as well as improved fuel efficiency and power output. Overall, the FORD 4.6L engine is a popular choice among enthusiasts and is well-regarded in the automotive industry for its versatility and performance.

The Coyote is a robust 4.6-liter 3-valve V8 engine developed by Ford Motor, designed to power a diverse range of vehicles from 1991 to 2019. Configured in a V-shape with an overhead valve design (OHV), the Ford 4.6L 3-Valve Coyote engine boasts a lineage within the Ford engine family that spans nearly three decades.

Originally introduced in 1991, the 4.6L 3-Valve engine marked a significant evolution in Ford’s commitment to performance and efficiency. Its tri-valve design optimizes air and fuel flow, enhancing combustion efficiency and overall engine performance. The engine’s versatility made it a staple in various Ford models, contributing to its longevity in the automotive landscape.

Over the years, the 4.6L Coyote engine has seen iterative improvements. Technological advancements in fuel injection, ignition systems, and overall engine management have been key focal points. These enhancements have translated into improved horsepower, torque, and fuel efficiency, making the 4.6L 3-Valve Coyote engine a reliable choice for a wide range of Ford vehicles.

As of 2019, the Coyote engine has undergone refinements, with the latest models benefitting from state-of-the-art engineering. Ford’s commitment to innovation is evident in the precise calibration of engine parameters, resulting in optimal performance across various driving conditions.

Fraser Engines specializes in remanufactured gasoline engines tailored for diverse applications. Our comprehensive packages encompass the cylinder block, rotating assembly, cylinder head, valve train, and installation gasket set.

Differentiating ourselves from conventional practices, Fraser Engines adheres to a stringent blueprinting process for all long blocks. Instead of repairing damaged crankshafts, cylinder blocks, or heads, we replace them with new components, ensuring longevity and reliability. Our commitment to quality is further emphasized by using materials from the same suppliers as the OEM, and precision machining on CNC equipment guarantees strict adherence to or surpassing OEM specifications.

At Fraser Engines, we prioritize excellence in every facet of our remanufactured gasoline engines, offering a reliable and high-performance alternative for your vehicle.

Overview

| Metric | Value |

|---|

| Engine family | Coyote |

| Displacement | 4.6 liters |

| Aspiration | Naturally aspirated |

| Configuration & cylinders | V configuration, eight cylinders |

| Vehicle engine orientation | Longitudinal |

| Valve configuration | Overhead valve (OHV) |

| Assembly sites | Various, including Romeo, Michigan |

| Predecessor | Ford 4.6L Modular V8 |

| Successor | Currently none |

IF YOU DON’T SEE YOUR VEHICLE – CALL FRASER SALES

The 4.6L 3-valve (3V) Ford Modular V8 engine was used in various Ford and Lincoln vehicles, primarily from the mid-2000s through the early 2010s. Below is a list of the vehicles that came equipped with the 4.6L 3V engine:

Ford Vehicles

- Ford Mustang GT (2005-2010)

- The 4.6L 3V was the standard engine for the Mustang GT during this period, providing improved power and torque over the previous two-valve version.

- Ford F-150 (2004-2010)

- Available in various trim levels, the 4.6L 3V was used in Ford’s flagship pickup truck, offering a balance of power and fuel efficiency.

- Ford Explorer (2006-2010)

- Used in both the rear-wheel-drive and four-wheel-drive versions, providing sufficient power for the midsize SUV.

- Ford Explorer Sport Trac (2007-2010)

- This pickup-SUV hybrid benefited from the 4.6L 3V’s versatility and towing capability.

- Ford Expedition (2005-2009)

- The 4.6L 3V was offered as a base engine for the Expedition, with the 5.4L V8 being the upgrade option.

Lincoln Vehicles

- Lincoln Town Car (2005-2011)

- The Lincoln Town Car, known for its luxury and smooth ride, used the 4.6L 3V as part of its powertrain lineup.

- Lincoln Mark LT (2006-2008)

- The luxury version of the Ford F-150, the Lincoln Mark LT, used the 4.6L 3V in some versions during these years.

Mercury Vehicles

- Mercury Mountaineer (2006-2010)

- The Mountaineer, which is closely related to the Ford Explorer, also offered the 4.6L 3V as an engine option.

Overview of Vehicle Fitments

- Mustang GT (2005-2010)

- F-150 (2004-2010)

- Explorer (2006-2010)

- Explorer Sport Trac (2007-2010)

- Expedition (2005-2009)

- Lincoln Town Car (2005-2011)

- Lincoln Mark LT (2006-2008)

- Mercury Mountaineer (2006-2010)

STEP 1) ENGINE BLOCK DISASSEMBLY

Our journey begins with a thorough visual inspection of each engine block for casting defects. We meticulously disassemble the components, inspecting each part for damage and identifying the cause of failure. We remove oil and water passage plugs to guarantee optimal results during thermal cleaning. We select only premium castings for our marine blocks, insisting on replacements in all salt-water applications. For high-performance engines, we utilize premium cores, never employing repaired castings or sleeved blocks, preserving the authenticity of your classic car’s original block casting with our skilled technicians’ craftsmanship.

STEP 2) ENGINE BLOCK THERMAL CLEANING

We elevate engine parts to a new level of clean with our thermal cleaning system. This process evenly distributes heat throughout the chamber, avoiding overheating or warping. Components are heated in an oxygen-deficient atmosphere, decomposing combustible hydrocarbons and leaving parts dry. We use the Ace RKE 230 oven exclusively for cast iron blocks, ensuring ash residue is effortlessly removed in the subsequent stainless steel shot blasting phase.

STEP 3) ENGINE BLOCK SHOT BLASTING

Our shot-blasting method employs stainless steel shot to remove surface contamination like rust, creating a smoother finish. This step is vital for detecting surface and subsurface defects during quality inspection. The peening process imparts compression strength to the metal, preparing it for a preliminary defect inspection.

STEP 4) ENGINE BLOCK MAGNAFLUXING

We use magnetic particle inspection to detect cracks and imperfections in ferrous engine parts, ensuring the highest quality for our cast iron blocks. Before proceeding to aluminum blocks, we explain their specific cleaning, testing, and defect checking processes.

STEP 5) ENGINE BLOCK HIGH PRESSURE WASH

Aluminum engine blocks first encounter our AXE SW20 OS spray cleaning system, which removes all foreign material with its powerful spraying action and multi-integrated nozzles. This step is crucial for a thorough inspection.

STEP 6) ENGINE BLOCK SONIC CLEANING

We use ultrasonic cleaning for aluminum blocks, known as the benchmark in cleanliness. This method reaches inaccessible areas, breaking the bonds that hold small particles to surfaces. Post-cleaning, the block undergoes pressure testing.

STEP 7) ENGINE BLOCK PRESSURE TESTING

We employ the Delta Pressure tester to double-check for pinholes after magnafluxing and dye testing, ensuring the integrity of all castings used in our products.

STEP 8) ENGINE BLOCK PREPARATION

After a complete visual inspection, we repair minor casting defects, remove broken bolts, tap threads, and perform gasket surface repairs to minimize stock removal.

STEP 9) ENGINE BLOCK MACHINING

We use the RMC CNC V40 enclosed machining center for precise and versatile machining. This computerized machine measures and levels blocks, measures deck heights & cylinder bore sizes, eliminating operator error. Our machine determines Ra finish based on block type and gasket used, utilizing CBN cutters and checking surface finish with the Mitutoyo SJ-301.

STEP 10) ENGINE BLOCK ROD RECONDITIONING

The Sunnen LBB-1600 Hone, measuring accuracy within .0001″, is our choice for precision rod reconditioning and pin fitting, ensuring honed bores equal to or better than new rods. High-performance engines are fitted with ARP high-strength bolts and nuts prior to this step.

STEP 11) ENGINE BLOCK HONING

We are the first to use Rottler’s newest cylinder honing machine, ensuring the most accurate honing with cylinders finishing within .0001″ roundness and straightness. This machine continuously analyzes and corrects the bore, maintaining evolving engine designs’ critical oil clearances and machining tolerances.

STEP 12) ENGINE BLOCK HIGH PRESSURE WASH

After precise machining, our blocks undergo a second high-pressure wash cycle, ensuring absolute cleanliness for final assembly.

STEP 13) ENGINE BLOCK SONIC CLEANING

We ultrasonically clean all parts prior to assembly, ensuring the ultimate cleanliness level. This method reaches every surface and internal area, providing the cleaning force required for the most stringent standards.

STEP 14) ENGINE BLOCK ASSEMBLY

Each assembler at Fraser Engines conducts a thorough visual inspection and measures parts for proper size. We fit blocks with new cam bearings, oil restrictors, relief valves, new water and oil plugs, and more. Cylinder heads are installed with new bolts and gaskets, and each cylinder’s seal integrity is checked. The final inspection by our assembly manager ensures the highest quality for your remanufactured engine.

Fraser Engines is committed to delivering engines of exceptional quality and performance. Our rigorous, detailed remanufacturing process ensures every engine we deliver meets our high standards and exceeds your expectations.

Use conventional or break-in oil (non-synthetic) for the first 600 miles of operation. Do not drive for long periods at any single speed, always vary your speed. Do not tow a trailer or put other heavy loads on the vehicle. Check the engine oil and coolant levels daily.

At 600 Miles change the engine oil and filter using conventional (non-synthetic) oil. Check fuel and ignition settings; adjust valves (where applicable).

After the first 5,000 of service synthetic engine oil may be used. Follow your vehicle owner’s manual for service intervals.

Engine Block

Engine Block